High performance bricks in various quality are made:

- Tabular/Fused Alumina based refractory:

- Very high refractoriness and abrasion resistance.

- Used for combustion/choke of Tread reactor and main reaction section of Carcass reactor.

- Alumina-Zirconia refractory

- Good Thermal Shock resistance and high refractoriness.

- Suitable for use in reactor sections where temperatures go beyond 1900 0

- Alumina-Chrome refractory

- Excellent chemical resistance to highly corrosive slags.

- Used for choke area of Tread and main section of Carcass reactor.

- Mullite Refractory

- Made with high purity sintered/fused mullite grains.

- High creep and corrosion resistant.

- Used for lower temperature (1550 0C- 1750 0C) sections of the reactor.

- Andalusite based refractory

- Low iron and alkaline impurities

- Volume stable and corrosion resistant

- Suitable for use in lower temperature sections of the reactor

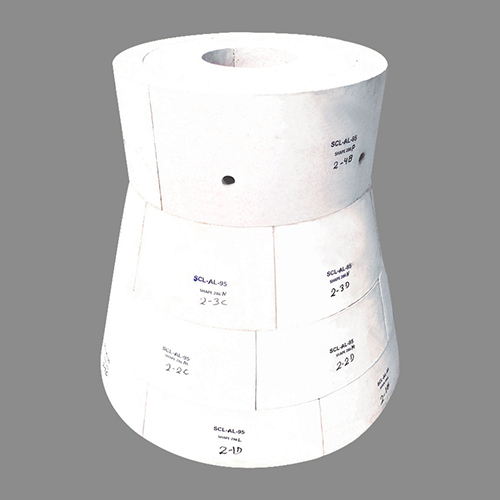

- Bubble Alumina based insulation refractory is used for back-up lining of the carcass reactor.

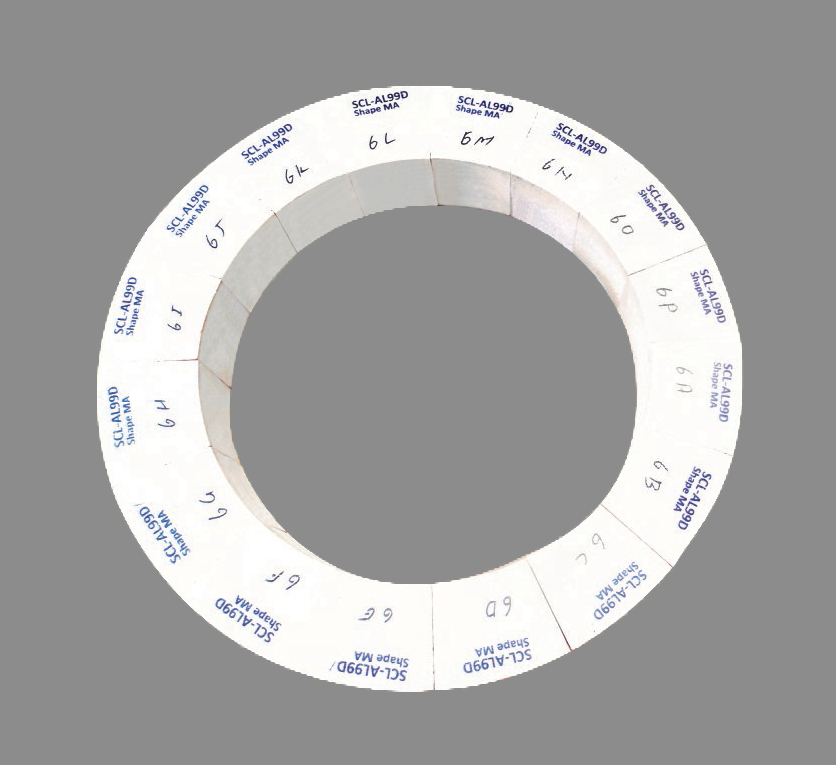

Choke assembly for tread reactor